Blog Archives - Zosi Learning

Trending Topics

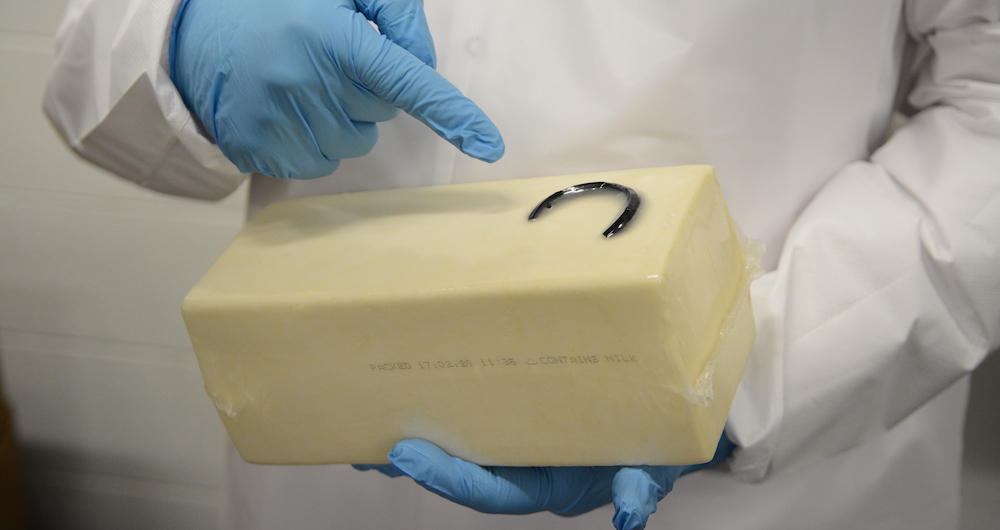

HACCPFood DefenseKosherEMPLeadershipInternal AuditingSQFPCQI7 Ways to Prevent Foreign Material in Food

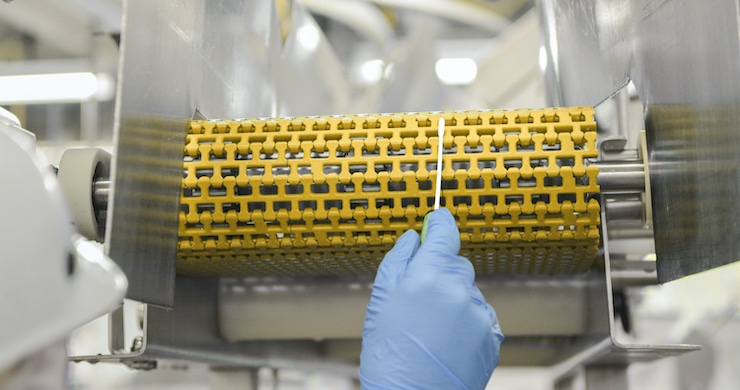

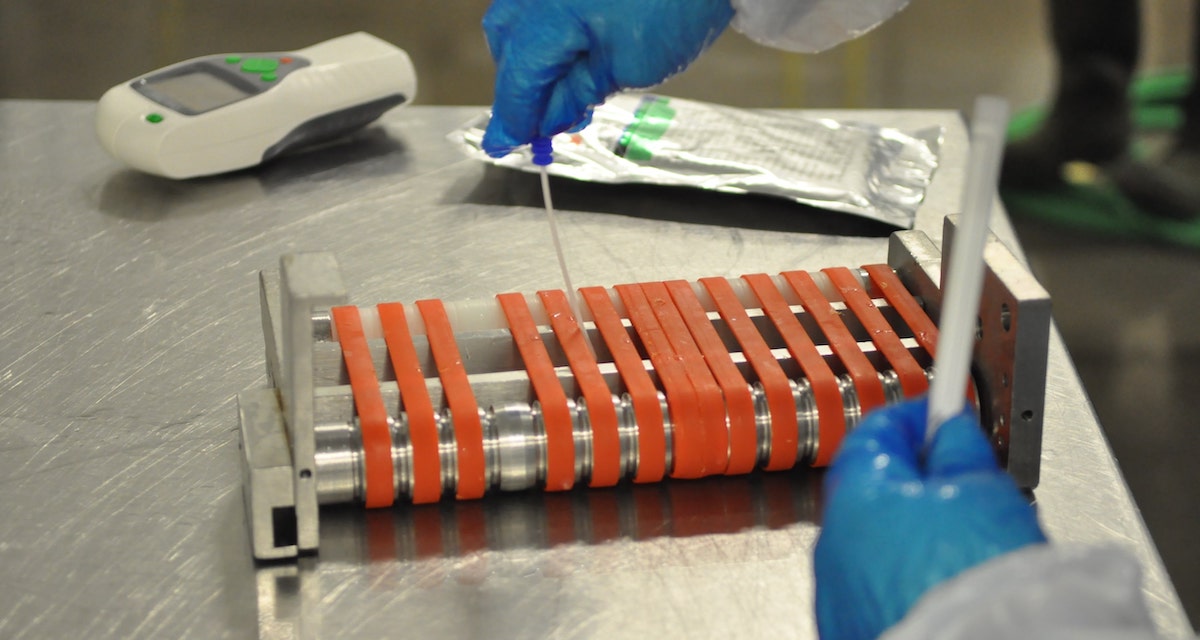

Perform Thorough Risk Assessments Preventing foreign material in your production begins with robust risk assessments of your delivery and storage areas, production lines, building and facility perimeter. Don’t rush and be sure to pay attention to the details. Potential risks include loose floor aggregate, caulking in the ceiling or wall panels, overhead lights, nuts, bolts […]

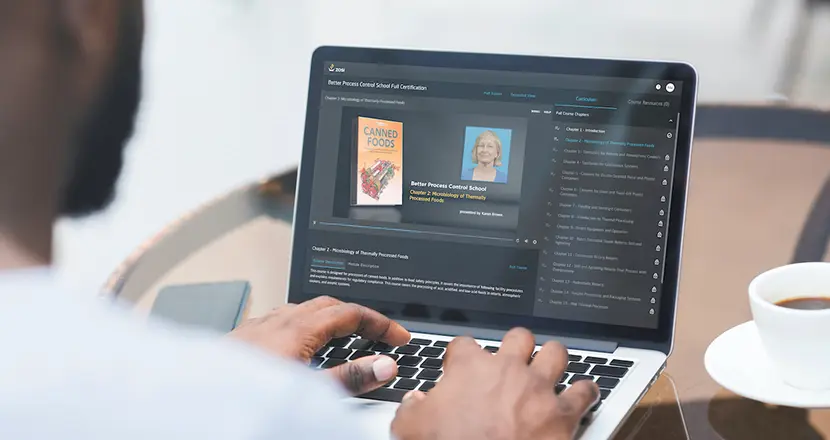

3 Reasons Why Zosi Learning is the Best Place to Earn Your Better Process Control School Certification

In the dynamic landscape of food processing, ensuring the highest quality and standards is a non-negotiable. As the demand for top-notch control and management processes continues to rise, selecting the right Better Process Control School (BPCS) training becomes paramount. In this blog post, we will uncover 3 reasons why Zosi Learning is the best place […]

Internal Auditing: 5 Tips for Building Your Best Internal Audit Team

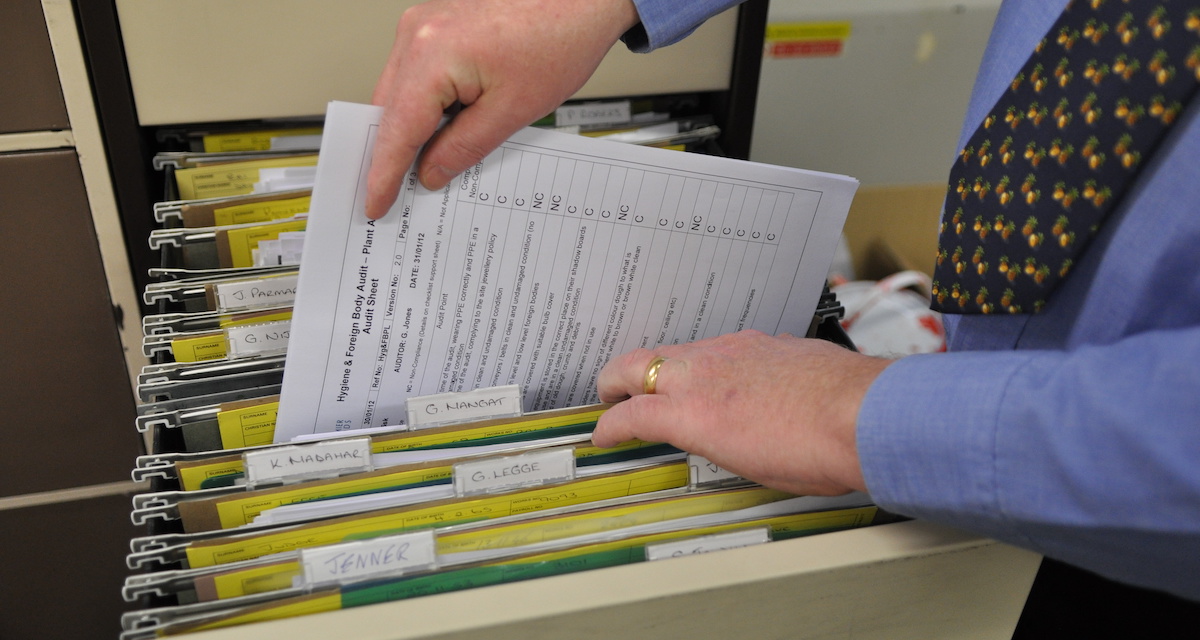

Effective internal audits should never be conducted by a single individual. Instead, your facility must assemble a multi-disciplinary team of at least two or more individuals to conduct robust internal audits. The size of the internal audit team always depends on the size of the operation. Team members must possess foundational internal audit training. This […]

Subscribe to

Insider Insights

What you need to know before becoming a PCQI

Are you thinking about becoming a PCQI? Does someone on your team to need to take PCQI training? Meet our lead instructor, Jeff Chilton, as he discusses what makes a PCQI successful, the key knowledge a PCQI needs and how he thinks training should be approached. Intertek Alchemy is excited to share that Jeff Chilton, VP […]

Mitigate Supply Chain Risks with These Two Steps

In food production, risks are everywhere. As discussed in our prior article, risk assessment. This step helps identify suppliers that need the most scrutiny due to their higher threat level. There are three critical steps in this process. Develop a risk rating system toevaluate how much you buy from a single supplier, their costs, reputation, and […]

7 Steps to Develop a Risk Mitigation Mindset

In the food industry, leaders must create and maintain a food safety culture that empowers teams to identify and respond to issues before they become serious problems. The most effective path toward this culture is through a risk mitigation mindset. Risk mitigation is the process of understanding certain risks and threats, accepting that they exist, […]

Training and Skills for a New Generation of Food Defense Experts

At a time when the world’s food supply remains fragile and unpredictable, a new generation of food defense professionals is emerging. Many food professionals are taking on this role for the first time or with limited experience. Others lack historical knowledge that left with colleagues during the great resignation. These employees might have experience with […]

Advance Your Food Safety Culture with a Stronger Sense of Purpose

Regulations are essential in protecting the quality of foods everywhere. But they can only go so far. Food safety can only truly be effective when it’s part of a mature food safety culture. Part of that culture involves understanding who is responsible for food safety and why it’s important. Some frontline workers might say it’s […]

New Customizable Food Safety Culture Training Program Drives Continuous Improvement and GFSI Compliance

Intertek Alchemy is excited to announce a new online food safety culture training program for food industry leaders that builds and maintains an informed culture coalition within their organizations. The unique solution includes GFSI-based food safety culture instruction, complimented with a best practice case study and a food safety culture gauge that provides custom action […]

Internal Auditing Basic & Advanced Courses

When you look at it from the perspective of ISO 19011 – the guidelines for auditing management system – an internal audit can be defined as a systematic, independent, and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which the audit criteria is fulfilled.

Seven Principles to Building a Successful HACCP Program

Hazard Analysis and Critical Control Points (HACCP) plans are the backbone of any food safety program. They prioritize and control potential hazards in food production for the entire food supply chain.

Reinforce Food Defense with Managers, Supervisors and Frontline Employees

Most consumers are generally confident food manufacturers are taking every possible precaution to ensure the safety of the food they put on their tables. Inspections, regulations, and best practices can go a long way to keeping foods safe. But one of the biggest threats remains from within.

Companies Turn to PCQI Trained Professionals to Lead Food Safety Efforts

America benefits from one of the safest food sources in the world. But what does it take to keep it that way? At the end of the day, it all comes down to people, especially the Preventive Controls Qualified Individual (PCQI). The Food Safety Modernization Act (FSMA) created PCQI’s to establish a role that carries out […]

Food Defense 101: The Three Types of Food Defense Threat Motivations

Intentional adulteration is only carried out after careful study and preparation by an attacker – is your food defense program equally prepared to address such acts?

SQF Substitute Practitioners Explained

Under the Safe Quality Food (SQF) Code, Edition 9, substitute practitioners are now a mandatory component of your organization’s regulatory compliance. According to 2.1.1.4, Part B of the new SQF Code , site managers must designate a primary and at least one substitute practitioner for every site.

How to Meet Regulatory Requirements for HACCP

HACCP plans are the backbone of your food safety system. Built from the seven HACCP principles, these plans are mandated by regulatory bodies for the meat industry, the juice industry, and the seafood industry.

The 5 Factors That Guide Effective Internal and External Audits

Audits play an integral role in the successful production or manufacturing of food and beverages at a fundamental level.

Your Guide to Building an Effective OHS Program

Taking a proactive approach with an OHS program is crucial to prevention of incidents in your facility. Not sure where to begin? By following OSHA recommended safety practices it’s easy to break down the process into manageable stages.

Passover Prep: Special Kosher Certification Explained

In kosher production, there are special circumstances that warrant extra concerns and requirements. One of these is Passover. Passover spans eight days each spring and is one of the most widely celebrated Jewish holidays. During Passover, kosher consumers do not eat or possess any “chametz” or leavened grain (or its derivatives).

The Who, What, When and Why of PCQIs

The Food Safety Modernization Act’s (FSMA) Preventive Controls for Human Food Rule ensures safe manufacturing, processing, packing, and holding of foods meant for human consumption in the US.

Addressing the 5 Dimensions of Food Safety Culture

Safety culture, more specifically food safety culture, has been a focus more and more in the workplace as a key factor in providing the best possible product for your consumers.

Six Core Competencies of Leadership

How do you effectively lead a team in a time of relentless uncertainty? No matter your industry, we know times are difficult. Keeping on-site employees safe, making remote roles more productive, and coping with The Great Resignation feels like a never-ending struggle, but great leaders persist.

What is the Plan-Do-Check-Act (PDCA) Cycle?

PDCA stands for Plan Do Check Act. The PDCA cycle is a four-step quality management method used in business for the control and continuous improvement of processes and products. It’s also known as the Deming cycle, the Shewhart cycle, the control cycle, or PDSA (Plan Do Study Act).

2021 Review and 2022 Forecast: A Look Back and A Look Ahead

When we didn’t think things could possibly get any worse than they were in 2020, the year 2021 certainly gave it a run for the money. It has been a long year of continued challenges, increased costs, and extensive labor shortages. The optimism in the first quarter of putting the pandemic behind us with the […]

Food Defense 101: Understanding Food Defense Roles and Stakeholders

Different professionals from the public and private sectors contribute to food defense. Many of the familiar stakeholders involved in food safety incidents will be required in a food defense incident, but because intentional adulteration is a crime or an act of terror, additional groups will need to be engaged.

How to Prepare for a Kosher Inspection by Department

So, you’ve chosen to pursue kosher certification. Your visit from the rabbi is looming, so what can you do to prepare for the kosher inspection? Each department must keep up with certain routine tasks to ensure that the facility is ready for a visit from the rabbi representing the kosher certification agency.

Allergen Management Tips for Food Manufacturers

Allergenic foods pose a serious safety risk to your consumers, causing sometimes life-threatening medical reactions when exposed. As the CDC continues to report a rise in food allergies across age demographics, successful allergen management is an integral piece of food manufacturing.

Environmental Sustainability Best Practices at Home and Work

Environmental sustainability is a team effort. When you incorporate environmental sustainability into your daily routine, whether at home or work, you’re not only helping the environment for future generations but you’re also saving money and promoting company efficiency.

Food Defense 101: Key Activity Types

Food processors who fall under the Intentional Adulteration Rule (IA Rule) must conduct a vulnerability assessment as part of their food defense plan. A vulnerability assessment measures potential public health impact (e.g. severity and scale), degree of physical access to the product, and the ability of an inside attacker to successfully adulterate your products.

What is Food Defense Risk Analysis?

Risk analysis is a process that helps manufacturers identify and manage potential problems in their process or facility. A food defense risk analysis model has three components: risk assessment, risk management, and risk communication. Risk assessment refers to rating the severity and likelihood of a certain hazard or threat. Risk management refers to making decisions […]

What Makes an Effective Internal Auditor?

Your internal audit is only as good as the people completing it. Thus, the individuals selected must have the industry qualifications and auditing experience necessary to perform an effective internal audit. We’ve broken down the benchmarks for well-trained, qualified internal auditors by personal attributes, knowledge and skills, as well as experience and training below, so […]

HACCP vs HARPC: What’s the Difference?

Confused about the difference between HACCP and HARPC? You’re not alone. Both stem from the Food Safety Modernization Act (FSMA), a robust food safety legislation act enacted in 2011. The ultimate goal of each is to proactively identify food safety problems in your facility and correct for each. HACCP and HARPC are often used interchangeably, […]

Prerequisite Program Examples for Your HACCP System

Prerequisite programs, or PRPs, are essential to the development of effective HACCP systems. In theory, PRP’s act as the foundation of this system – the stronger a facility’s foundation, the stronger its food safety plan.

Active Shooter Readiness: How to Create an Emergency Action Plan

The number of active shooter incidents in the United States is currently 20% higher than in 2020. The words alone are enough to instill a sense of dread, let alone the statistics.

Continuous Improvement: Understanding Success with Six Sigma

Continuous quality improvement is more of a philosophy than a process or system. It requires commitment from everyone in the business. Everyone from senior management to frontline workers must adopt a mindset of continuously looking for ways to improve processes and systems by making them efficient and effective. Unsustainable continuous improvement efforts are those that […]

Arming Your Employees to Prevent Food Fraud

Food fraud is the deception of consumers using food products, ingredients and packaging for economic gain. Although food fraud has only recently received heightened attention, it’s been around a long time.

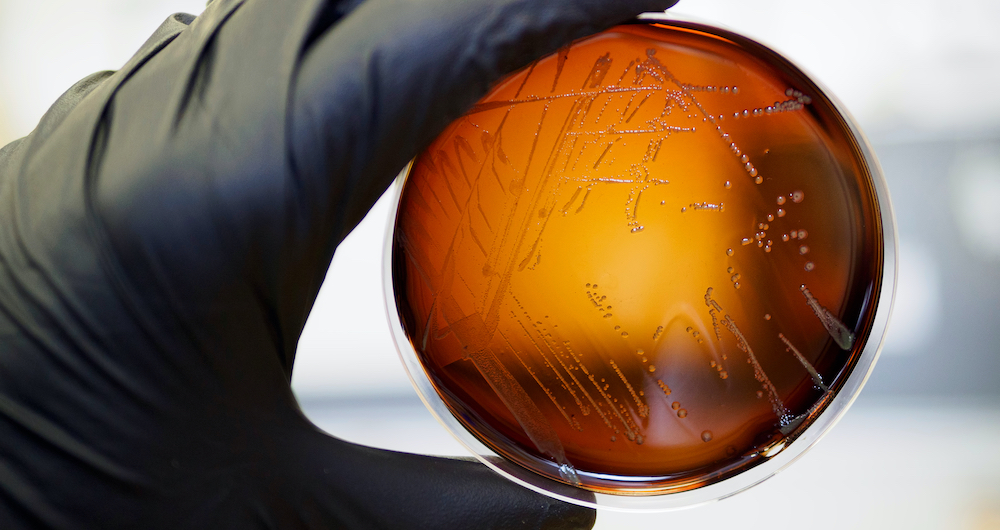

Five New Listeria Strains to Know

Cornell University researchers have identified five previously unknown strains of Listeria in United States soil. “This research increases the set of listeria species monitored in food production environments,” said Catharine R. Carlin, a doctoral student in food science. “Expanding the knowledge base to understand the diversity of listeria will save the commercial food world confusion […]

Continuous Improvement Processes: What is Lean Manufacturing?

Continuous quality improvement is the ongoing process of raising the performance of an organization (and thereby improving products, services, people, and systems) to provide added value for consumers and a better working environment for employees.

Getting Guidance on FSSC 22000: Benefits & Purpose

More and more, consumer become concerned about food safety. Incidents of foodborne illness and recalls are seemingly ubiquitous as supply chains globalize and controls struggle to keep up. Manufacturers must make efforts to address these vulnerabilities in their processes. One way to do so is to adopt a widely recognized food safety and quality standard, […]

6 Quick Tips for Conducting Effective Internal Audits

The best way to stay compliant is to conduct an internal audit. Below are Zosi’s tips for conducting an effective internal audit:

FDA-Recognized Food Allergens

Under the Food Allergen Labeling and Consumer Protection Act (FALCPA) the FDA recognizes the following food allergens in the US:

A Quick-Guide to Common Kosher Symbols

Whether you are a kosher food manufacturer or a kosher consumer, a basic understanding of kosher food labels is necessary to ensure the products you handle at work or home abide by kosher dietary laws. Certifying agencies use distinctive symbols to label kosher-certified foods. However, some additional universal designators help consumers immediately identify ingredients in […]

Improving Risk Communication for Your Consumers

Food safety, both at home and at large, is an increasingly complex enterprise. These dynamic and multifaceted systems necessitate increased transparency in communicating food safety information to all parties from farm to fork.

Three Strategies for Workplace Harassment Prevention

Think workplace harassment could never be an issue in your facility? Think again. Two recent studies by The Daily Campus report that one in three women experienced sexual harassment in the workplace. Of these, over 70% did not report it.

Sustainability Solutions for Produce Manufacturers

You’ve probably noticed more than a few farm-to-table restaurants popping up in your city. This trend is a direct result of modern-day consumer behavior and shifting values. At home, we’re increasingly aware of and concerned about every point in the food supply chain, from sustainable agriculture to eco-friendly food packaging.

Welcome To the New Us

You may be thinking that Alchemy Academy looks a little different today, and you’re right. Today marks our official transition to Zosi, a completely redesigned and re-engineered brand and learning marketplace.

Cultural Sensitivity During Your Visit from the Rabbi

So, you’ve decided to include kosher foods in your production. You’ve studied guidelines, perfected processes, and even read our blog on what to expect during your kosher inspection, but there may be a missing piece of the puzzle. The rabbi who visits your facility will be an Orthodox Jew. Thus, it is critical to familiarize […]

The Case for Audits: Potential Pandemic Blind Spots

Much ink has been spilled detailing the impacts of COVID-19 on the food industry. News outlets, blogs, webinars, and more continue to relay stories about food processors overwhelmed with COVID-positive employees and grocery stores working around the clock to keep shelves stocked. With hospitals struggling to provide access to care, food safety is now perhaps […]

How to Avoid the Top FDA Regulatory Violations of 2020

In an unprecedented year for the food industry, regulatory compliance is top of mind as we all work to keep our employees, consumers, and products safe.

Food Defense Qualified Individual: Everything You Need to Know

Under the Food Safety Modernization Act Mitigation Strategies to Protect Food Against Intentional Adulteration (21 CFR Part 121) regulation, commonly referred to as the IA Rule, covered facilities must develop and implement a food defense plan.

Listeria Prevention: Best Practices for Avoiding and Responding to Contamination

Food processors regulated by FDA must comply with The Food Safety Modernization Act’s Preventive Controls for Human foods regulation.

How to Improve Performance with Inclusive Leadership

Diversity is all around us. Whether we’re on the processing floor or resigned to watching television in our living rooms, inclusivity has risen to the forefront of the world stage.

Food Safety Crisis Management Simulation: A New Way to Train

Around the world, food safety has transformed as a result of the COVID-19 pandemic. On the edge of a hopeful new year, crisis management planning has risen to the forefront of the food industry.

How Do I Become an SQF Practitioner?

Under the Safe Quality Food (SQF) Code, every SQF-certified company must appoint an SQF Practitioner. Your company designated you their SQF Practitioner. But what does an SQF Practitioner do, and what are the requirements for becoming an SQF Practitioner?

How to Meet HACCP Requirements for SQF

The Safe Quality Food Institute’s (SQFI) new code further bonds your SQF certification with Hazard Analysis Critical Control Points (HACCP) compliance. Does your team fully understand Edition 9 requirements?

2020 Review and 2021 Forecast: A Look Back and A Look Ahead

The following entry comes from the desk of Intertek Alchemy’s own VP of Consulting, Jeff Chilton.

SQF Edition 9: 6 Key Changes for Food Manufacturing Professionals

SQF Edition 9 is finally here! As facilities begin to implement the new code into their food manufacturing facility, it’s important to view this set of standards as an opportunity for continuous improvement.

Food Safety, Security, and Defense in the COVID-19 Pandemic

As COVID-19 cases soar across the country again, we’re reminded not only of the impacts pandemics can have on the healthcare system, but also on the food industry as a whole.

How to Perform Effective Internal Audits

The best preparation for an external audit is perfecting your internal audit processes. While each facility’s procedures will be unique to its operation and products, you can apply the following internal audit process best practices to perform and evaluate effective assessments in your facility.

5 Tactics for Stronger Regulatory Change Management

Beyond maintaining regulatory compliance, effective regulatory change management is critical to your food production and manufacturing business’s success and sustainability.

COVID-19 Safety Protocols: Managing Hotel and Restaurant Suppliers

Your hospitality business is once again open. Are your pandemic safety protocols far-reaching and evolving?

Five Core Benefits of PCQI Training

The Food Safety Modernization Act’s (FSMA) Preventive Controls for Human Food Rule requires every food manufacturing facility to employ a Preventive Controls Qualified Individual as part of their food safety team.

Easy As P.I.E: The Keys to Kosher Beverage Production

What makes a beverage kosher? The answer begins with a discussion of where and how kosher production impacts your beverage plant.

Tackle Internal Audit Checklist for Food Safety Audits

If it’s not written down, it didn’t happen. Performing your due diligence is vital to your food safety audit process’s success and, in turn, successful production or manufacturing.

What to Expect from a Kosher Inspection

Whether you’ve weighed the benefits of product diversification and have already entered the kosher food industry or you’re just getting your feet wet, you may find yourself curious about the steps to kosher certification.

6 Types of Infection Control Measures for the Hospitality Industry

As COVID-19 changes the way we interact and travel, hospitality management must adopt new solutions and re-assess their existing practices to combat infection transmission.

Your Guide to the Seven HACCP Principles

What is HACCP and where did it come from? HACCP, which stands for Hazard Analysis and Critical Control Point is a system that prioritizes and controls potential hazards in food production and its supply chain, arose around the 1960s.

Corrective Action Plans: Step Up Your Environmental Monitoring Program

Sound the alarm – your facility received a positive pathogen result, like listeria or salmonella. How can you address the issue?

Recognize the Difference Between Food Defense and Food Safety

Can you spot the difference between food safety and food defense? While both have an important place in your facility, each presents distinct characteristics and consequences.

How to Impress a Buyer with Your Food Safety Plan

After long months, you have carefully crafted a product you are certain customers will love; next is the ultimate goal: to see your product on store shelves or, better yet, featured on a menu.

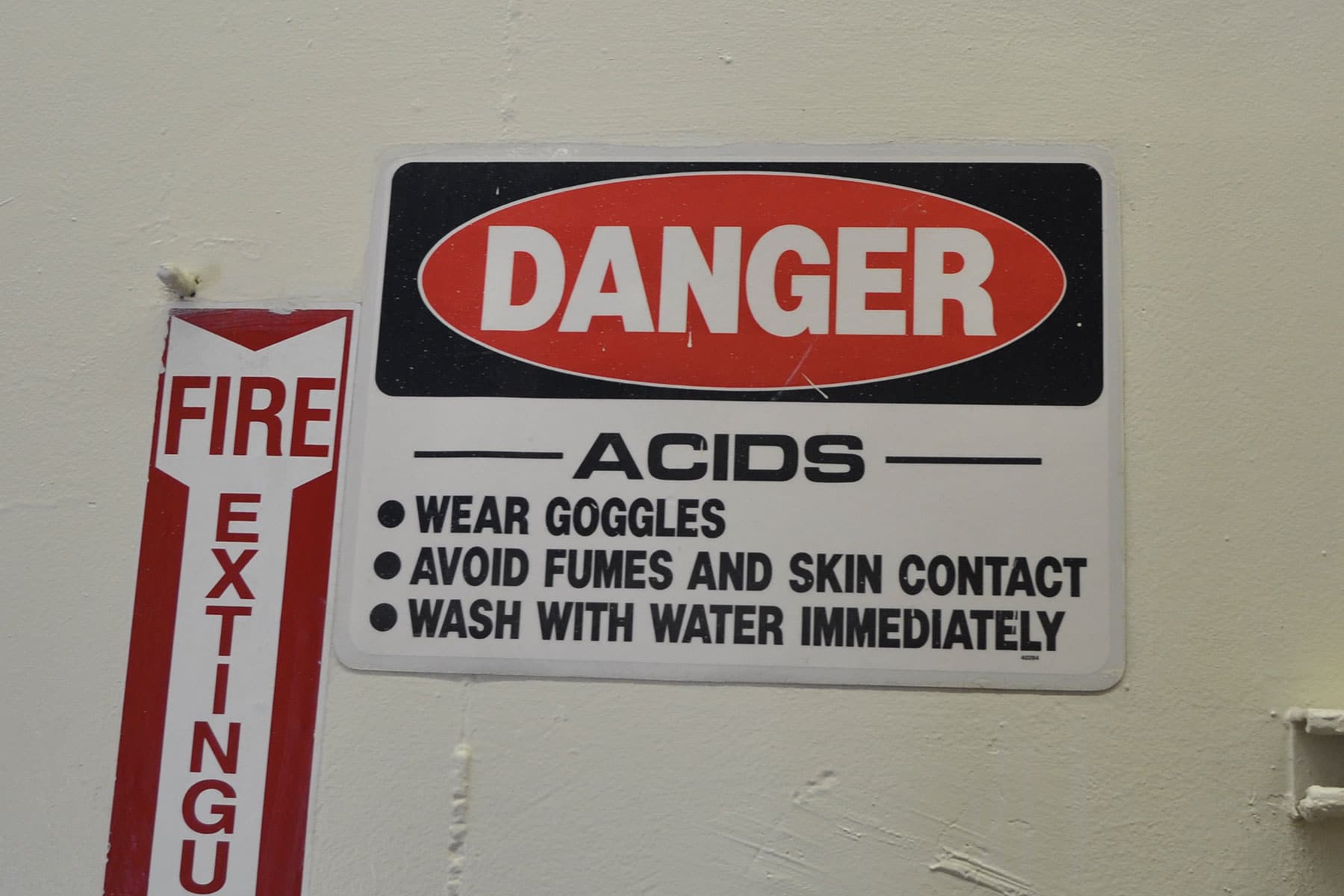

Use OSHA Best Practices to Prevent Chemical Catastrophe

Cue the stereotypical crime scene music. The toxicology is in. Oh, wait, the wrong kind? The National Institute of Environmental Health Services defines toxicology as a field of science that helps us understand the harmful effects that chemicals, substances, or situations, can have on people, animals, and the environment.

How Root Cause Analysis Strengthens Your Production

Root Cause Analysis is a method used to find the source of a problem once a problem has already occurred. By identifying the underlying cause of any incident, you can further prevent future incidents from happening.

The 5 Essential Steps to Creating Your EMP

You don’t have to be in the food industry to be aware of recalls that happen, seemingly more and more. Every day people are aware of listeria and E. coli that might have never heard of it forty years ago. How do we protect our products and keep from having to recall?

Your 5 Workers’ Rights Through OSHA

Even though worker injuries and fatalities have decreased, the food industry is statistically more likely to experience either of these.

Your Defense Against Intentional Adulteration

The idea of contaminated food brings up images of court jesters doing taste tests to make sure that kings and queens aren’t poisoned. Stories of intentional adulteration go back hundreds of years.

7 Steps to Effective Sanitation

As human beings, we all feel a need for cleanliness, hygiene, and sanitation when it comes to our food preparation.

What Kosher Means to Your Facility

While the word “kosher” has entered mainstream culture references, kosher food production demands strict adherence to a set of religious rules.

How to Avoid Top Audit Non-Conformances

In the food production industry, the Global Food Safety Initiative, or GFSI, performs audits that act as unbiased, independent evaluations of food safety and quality systems.

Taking Control of Your HACCP System

Implementing a HACCP System requires that both Prerequisite Programs and HACCP Plans are implemented. Prerequisite programs are programs that are put in place in the facility to control hazards in the environment, preventing contamination of the product.

How to Protect Your Consumers from Allergens

Governmental regulations, such as the Food Safety Modernization Act (FSMA), have drastically impacted how food producers perform allergen control. Activities that were formerly merely suggestions are now compulsory in order to minimize the risk of allergens in food products.

Never Miss an Update.

Never Miss an Update.